Industry-Leading Automation Expertise

ITW CER is widely regarded as an industry leader in hot stamping automation. We have over 80 years’ experience producing thousands of automated solutions as well as unmatched knowledge of the entire hot stamp and heat transfer processes. Our equipment, robust project management and targeted market-specific expertise allow us to provide automations tailor-made for optimal performance on your unique application.

Automating a hot stamp or heat transfer decorating line provides opportunities for:

Increased

- Output/productivity

- Lines speeds

- Quality

- Safety

- Consistency/repeatability

Decreased

- Reject/scrap rates

- Man power

- Factory lead times

Project Management

Needs Analysis

- The best possible solution is identified for the application at hand

Stand Out Design & Build

- Dedicated mechanical engineers’ team

- Dedicated software engineers’ team

- Dedicated field engineer (fine tuner)

- Dedicated artwork engineer for complete solution design (dies, tooling, etc…)

Proactive Communication

- Project managers dedicated to the project with a day to day management

ITW CER engineers are highly skilled in analyzing a wide range of factors in order to present the best possible technology for a particular product decorating challenge.

Our engineers carefully consider:

- Part Characteristics

- Decoration Size and Complexity

- Production Environment

- Safety Requirements

- Production Speed & Volumes

- Up- and/or Downstream Processes

- Compliance/Validation Requirements

- User Requirement Specification

- Operator Skill Level

- Application Performance Requirements & Environment

The unmatched expertise of our mechanical/electrical/controls engineers and process experts allows us to design automations with market-leading efficiency and precision.

We listen carefully to our customers’ specific needs at each stage of development; from the quoting through the final design review. Our proactive approach to customer communication ensures superior outcomes.

ITW CER has unmatched expertise in creating high-speed rotary and linear automations custom-designed to optimize efficiency and performance in each application.

| Loading Feeder | Vibrating feeder bowl with hopper, automatically supplies precision aligned parts to the decorating system. |

| Feeding Diverter | Feeder bowl enables feeding into two different machines. |

| Hot Stamping Machines | Two Quadrax 2M2N systems (each with its own conveyor) are fed inline by the same feeder |

| Outbound Conveyor | Decorated parts from both systems are fed onto a single conveyor belt. A push bar system at the end of the conveyor was specially designed to ensure parts are not damaged by falling onto each other. |

| Hot Stamping Systems | 2 Ultimax 2M2N Systems |

| Feeder | Both systems are fed by a single FlexLink feeder – doubling production speed |

| Stamping Heads | The customized Ultimax systems feature 4 direct stamping heads (3 for side printing and 1 for top printing) and CVI system for side and top. |

| Speed with Flexibility | Two configuration options. The first option allows for both machines to print the same part (effectively doubling production speed). The second option is for a parts to receive one decoration pass from the first machine and a second decoration pass from the second machine (allowing multiple design steps to be integrated into a single solution). |

| Outbound Conveyor | Flexlink system allows parts to be quickly fed from one system to the other. |

| Loading Station | Specialty loading station designed with advanced understanding of ergonomic momentum (based on piece size and weight) for superior performance. |

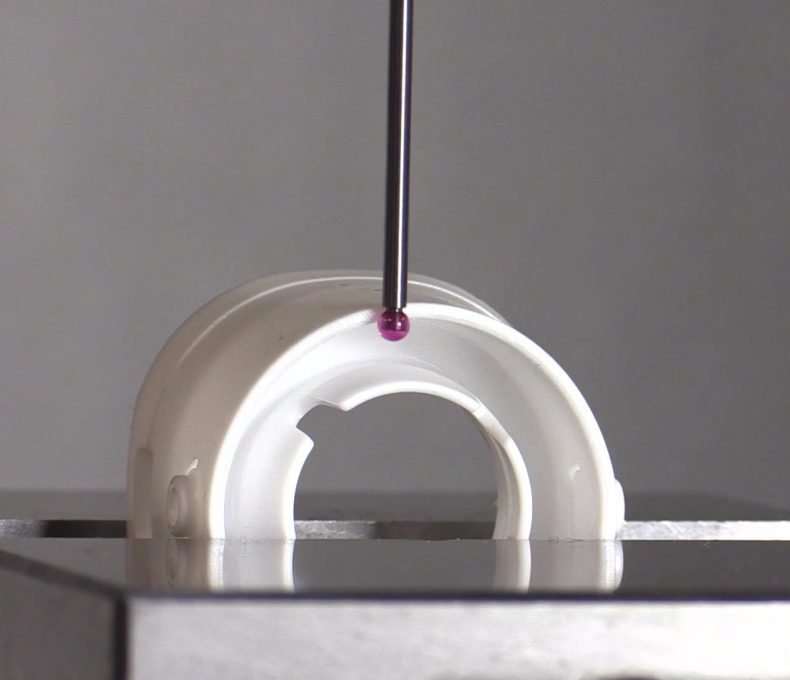

| Printing Support | Tooling specially designed for simple and fast part loading. Automatic locking ensures precision and speed. |

| Precision Alignment | 2.5 m linear axe transports the part to every station. Titling table aligns parts in proper position for stamping. |

| Cleaning Area | Prior to decoration, each part is pneumatically cleaned with a vacuum/ionized air brush that carefully follows the shape of the part surface for consistently good results. |

| Stamping Heads | Two servo driven printing heads with four foils advances cover wide printing areas. |

| Safety | A light curtain lockable door on the back side, and safety carpet ensure operator safety. |

Over the past 80 years, ITW CER has developed particularly deep expertise in automations for the cosmetic, automotive, fragrance and spirit glass, closure markets.

Cosmetic Market

- Thousands of different cosmetics solutions completed

- Systems accommodate a variety of feeder, ejection systems and peripherals

- Short run to high volume projects

Glass Decoration (Fragrance & Spirit Markets)

- Hundreds of automations completed

- 30 years’ experience

- Robust/efficient automated systems

- A single source combining screen printing primer application and hot stamping

- Decorate challengingly shaped parts

Closures Market

- Many full speed automated solutions for closure caps

- Systems run 24/7 for decades

- Quick dies change system

- Easy tooling change

- Embossing possible inline

Automotive Market

- Highly complex automotive solutions completed

- Tooling and dies development

- Compliance with stringent custom specifications

- Small interior to large exterior parts

- Ergonomically adapted