Die Department

Experts at Creating the Ideal Die for Your Unique Application

CER produces standard and custom dies that provide market-leading efficiency.

Our toolless Magnetic Quick-Change Die Mounting System (unique-in-the-market) enhances operator safety while generating important cost and time savings.

Our extensive range of die technologies include:

Silicone Dies

- Flat, Contoured, Crowned, Multi-Level

- Single or Dual Durometer

- Photo-etched and Machine Engraved

- Die Finishing

- Traditional and Magnetic Mounting Formats

Metal Dies

- Steel, Brass

- Flat and Contoured

- Die Finishing

- Traditional and Magnetic Mounting Formats

Precision + Efficiency

- Tool-less die changeover up to 90x faster (restart production in under 5 minutes)

- Up to 50% improvement in mounting accuracy (Magnetic Quick-Change Die Mounting)

- Crowned, contoured and multi-level stamping with CNC machine engraved molds

- Market-leading die capacity

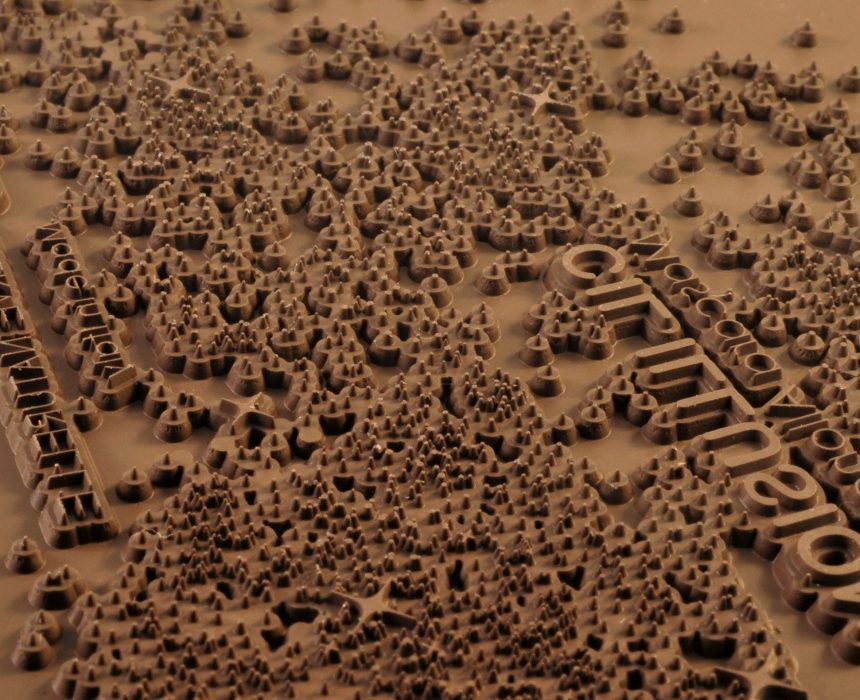

CER produces durable, high-precision silicone dies that deliver crisp, clean, impactful decoration to your part. Silicone rubber dies are used to hot stamp foil and heat transfers onto flat, contoured or cylindrical-shaped products.

Our dies provide excellent thermal conductivity, superior conformity to surface variations and high-impact visual performance with wide range of foils.

CER dies provide:

| Superior Formulations | For high-speed and long dwell time applications, our Thermosil® formulation provides heat recovery to the die surface required for reliable performance. |

| Superior Silicone-to-Metal Bond | In addition to die longevity, this provides superior repeatability from die-to-die. |

| Magnetic Die Mounting Systems (optional) | Toolless die changeovers in seconds while achieving up to 50% improvement in precision alignment. |

| Graphic Art Expertise | Our graphic arts experts- eliminate “lost in translation” errors when it comes to creating your artwork. |

| Die Finishing (LINK TO SECTION BELOW) | We can save you time by providing a completely “ready-to-use” die. Hole drilling, matching dovetail and special trims are some of our die finishing services. |

Our wide variety of die formats allows CER to identify a solution ideally suited to your unique application.

| Shapes | |

| Type | Common Uses |

| Flat | Vertical stamping, peripheral and roll-on applications |

| Contoured | Decoration that precisely matches a contoured part |

| Crowned | Eliminate air entrapment or to allow for heat sinks in plastic parts |

| Multi-level | Accommodate small height differences in parts to be decorated |

| Durometers | |

| Type | Overview |

| Single Durometer | Dies ranging from 50 to 90 durometer to meet a wide variety of needs |

| Dual Durometer | Enhanced capability to stamp combination of fine and bold graphics or better conformity to part variation |

| Mold Styles | |

| Type | Benefits |

| Machine-Engraved |

|

| Silicone Rubber Formulations | Hardness | Character Height | Rubber Thickness | Aluminum Thickness |

| Ultrasil (Red): High Heat Endurance |

50-90 durometers available in all formulations (Shore A)

Dual durometer is also available |

0.6mm reliefs standard | 1.6 mm relief | 15mm standard |

| Thermosil (Brown): High Heat Endurance PLUS Enhanced Thermal Conductivity |

60-90 durometers available | 0.6mm reliefs standard | 1.6 mm relief | 15mm standard |

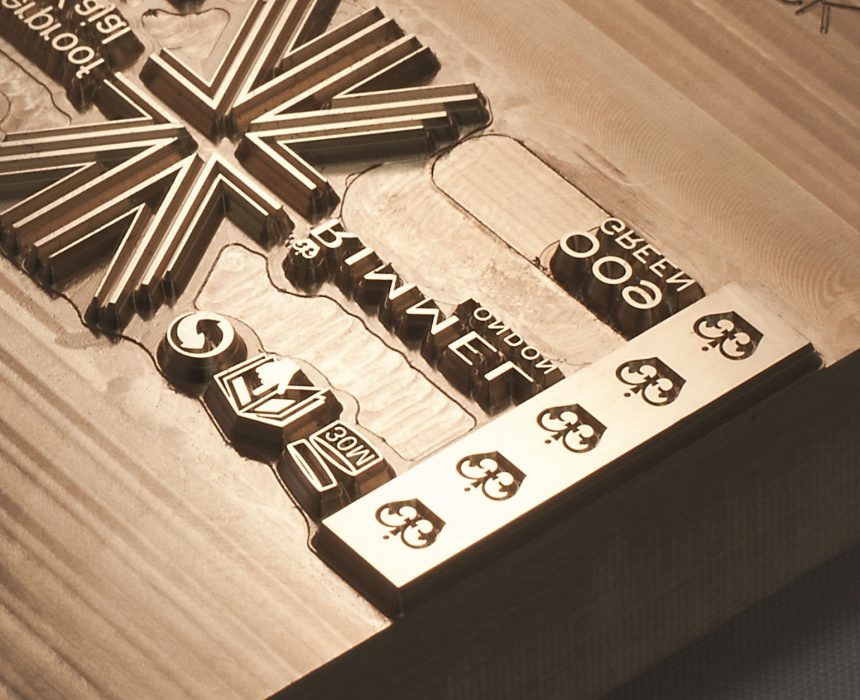

Metal dies provide excellent heat transfer characteristics for applications requiring an embossed appearance on flexible materials. Additionally, metal dies provide strong visual impact, high durability, excellent heat recovery and compatibility with challenging substrates.

CER dies provide:

| Die Finishing (LINK TO SECTION BELOW) | Completely “ready-to-use” dies. Hole drilling, matching dovetail and special trims and more. |

| Market-Leading Fine Graphics | Detail as small as 0.1 mm point type on brass dies |

| Graphic Art Expertise | CER graphic art experts eliminate “lost in translation” when creating your artwork. |

| Magnetic Die Mounting Systems (optional) | Toolless die changeovers in seconds while achieving up to 50% improvement in precision alignment. |

| Shapes | |

| Type | Common Uses |

| Flat | Vertical stamping, roll-on and peripheral applications |

| Contoured | Decoration that precisely matches a contoured part |

| Materials | |

| Type | Overview |

| Brass | Brass dies are ideal for mid-sized production runs. They are less durable than steel but significantly more durable than magnesium. Brass is particularly well suited for applications requiring contoured dies. |

| Steel | This is the most durable type of metal die and the most cost-effective for high volume applications. Steel dies are ideal for high volume production runs on consistent parts. |

| Engraving | |

| Type | Benefits |

| Machine-Engraved |

|

CER offers complete die finishing services for all of our dies. This service includes;

- Hole drilling / equipment adaptation

- Specialty trims (vs. square or rectangle)

- Dovetail machining

Silicone vs. Metal Dies

Which die material is best for my application?

Silcone Dies

- High impact pigment, metalic, holographic or prismatic impact

- More cost-effective than steel or brass

- Less pressure required

- Better conformity to slight surface variations

- No plastic deformation around artwork area

Metal Dies

- High impact pigment, metalic, holographic or prismatic impact

- Embossed visual effect

- Higher printing speeds

- Longer life

- May cause plastic deformation

| Rubber Dies | Metal Dies | |

| Materials Available | Various for specific applications – high temperatures, quick heat recovery, & high strength | Magnesium Copper Brass Steel |

| Average Die Life | Contoured – X Flat – 2X |

Magnesium – Y Copper – 4Y Brass – 18Y Steel – 20Y+ |

| Surface Variations (sinks) | Will Compensate | No Compensation for Sinks |

| Variation in Material Thickness | Will Compensate | No Compensation |

| Set-up Time | Quick Process | Lengthy Process |

| Pressure Requirements | 350 lbs. Per sq. inch (HS) 500 lbs. Per sq. inch (HT) |

1000 lbs. Per sq. inch |

| Temperature Requirements | 100F > Metal (approximately 300-400F) |

100F < Rubber (approximately 250-300F) |

| Dwell Time | 50% > Metal | 30% < Rubber |

| Decorative Finish | Foil/Transfer lays on top of substrate | Imbeds foil/transfer into surface |

| Price | Initial Set-up/Mold Charge Die Cost < Metal |

No Set-up/Mold Charge Magnesium – $ Copper – 2X $ Brass – 8X $ Steel – 10X $ |

| Substrates *indicates preferred material |

ABS Acetal Acrylic Polyamide (Nylon) Polycarbonate PolyethylenePolystyrene PVC – Plasticized PVC – Rigid* SAN* UV Coating Epoxy / Epoxy Coating Polyurethane Wood |

ABS Acetal* Acrylic Leather* Paper* Polyamide (Nylon)*Polycarbonate* Polyethylene* Polystyrene PVC – Plasticized PVC – Rigid SAN UV Coating* Epoxy / Epoxy Coating Polyurethane* |