Optimal Solution Identification

Expert Guidance In Finding the Best Solution for Your Challenge

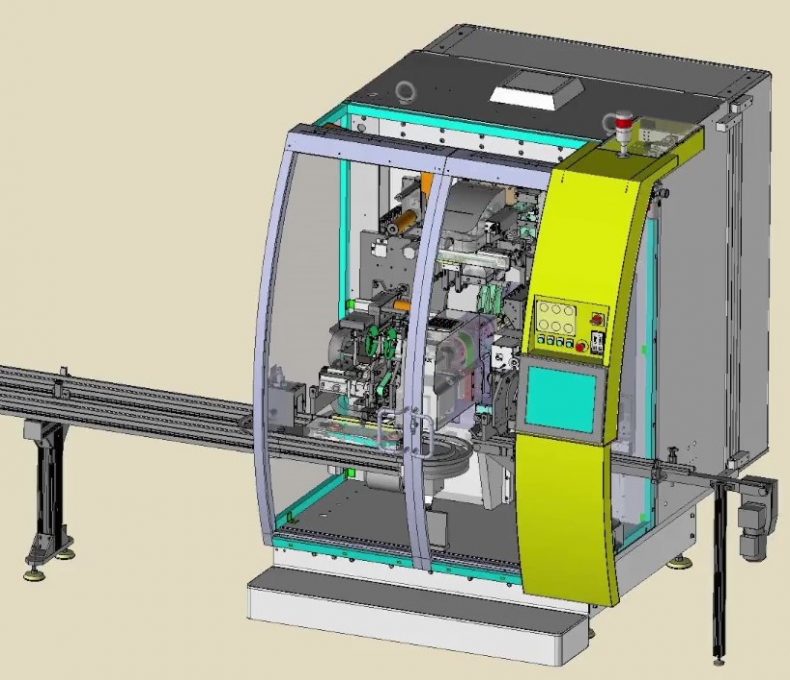

Over the past 80 years, CER has designed and manufactured thousands of hot stamp and heat transfer solutions carefully designed to meet precise application performance requirements. This experience combined with our passion for emerging innovative technologies, enables CER to provide expert process and application consulting, helping customers identify the best solution for their needs.

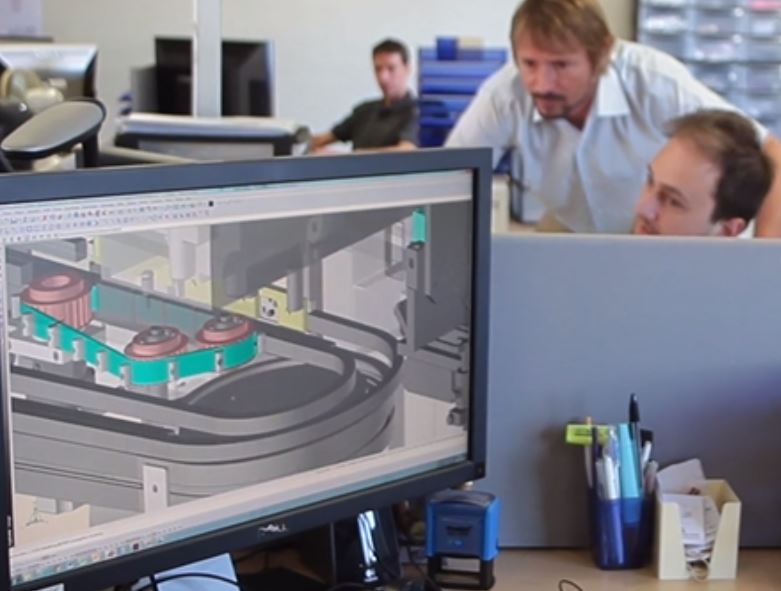

Our talented engineers have an average of 20 years’ experience each in creating solutions carefully designed to meet the needs of each application. We offer:

- Decades of High-Speed Automation Experience

- Total Solutions- Systems, Fixtures and Consumables

- Unmatched Knowledge of Entire Hot Stamp and Heat Transfer Processes

- Advanced Project Management

- Cutting Edge Technologies

- Market Specific Application Expertise

New Projects

Our detailed and deliberate process allows us to confidently identify the optimal solution for your product decoration challenge.

Decades of experience allow our engineers to anticipate any challenges so you don´t have to. To best understand your needs, we carefully explore a myriad of considerations including:

- Production volumes required

- Artwork complexity, size, location

- Substrate characteristics (dimensions, tolerances, surface features, etc.)

- Production Workflow (in-line and off-line elements)

- Consumable quality requirements

(foil, heat transfer label, dies, etc)

- Safety requirements

- Customer engineering skill level

- Application or market-specific performance requirements

- Compliance/validation requirements (possible integrated vision system)

Having achieved a comprehensive understanding of your needs, our team begins the process of matching them to available technologies. We consider a variety of elements including:

- Artwork generation or modification

- Stamping equipment format (vertical, peripheral, etc) and characteristics

- Required automation performance

- Die options – geometry & formulation adaptation

- Fixture options

- Foil/film/transfer label requirements

Once we have completed a comprehensive analysis of your needs and mapped out all key technology recommendations, CER can confidently present the optimal decorating solution for your application.

Optimizing Existing Projects

Existing projects also benefit from our Optimal Solution Identification service. Whether you are facing challenges with your current hot stamp / heat transfer line or if your line has been running well for years, a workflow and performance audit can provide many benefits including:

- Improved repeatability

- Cost savings

- Streamlined workflow

- Reduced scrap

- Improved Operator Knowledge (Data Dock Support in France)

- Longer system life

- Reduced downtime