Industry Challenges: We understand the challenges commonly associated with spirits packaging decoration. CER´s customer or technical support staff can provide insight on the following topics:

- Glass Bottle Decoration

- How to efficiently integrate screen printing and hot stamp decoration (quality screen printing ink, proper curing, superior adhesion) to ensure superior visual impact.

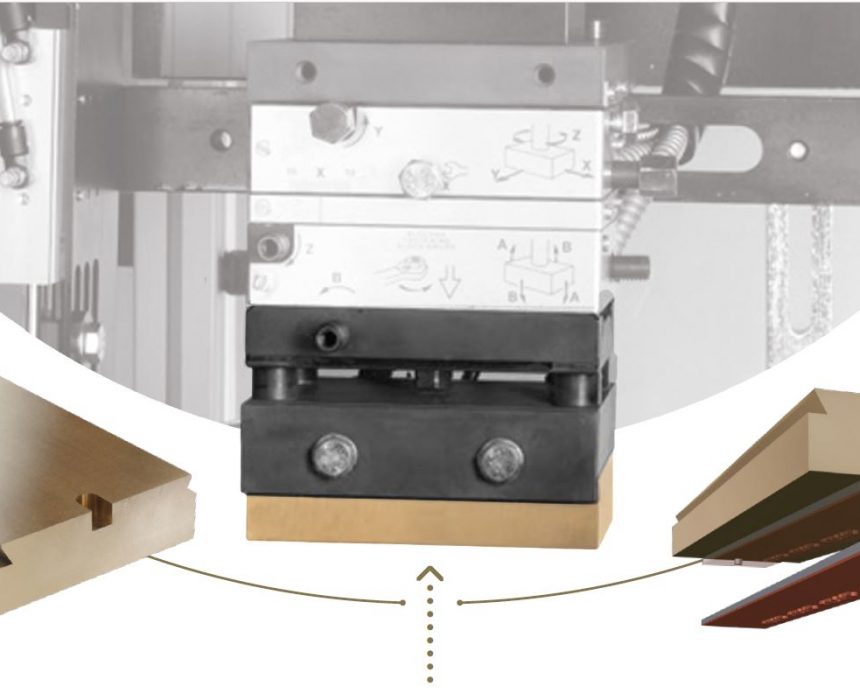

- Closure Decoration

- How to ensure precision registration of up to 0,2 mm at high speeds.

- Both Bottle & Closure Decoration

- How to ensure durable print with mechanical and chemical resistance capable of standing up to freezer, abrasion and vibration testing.