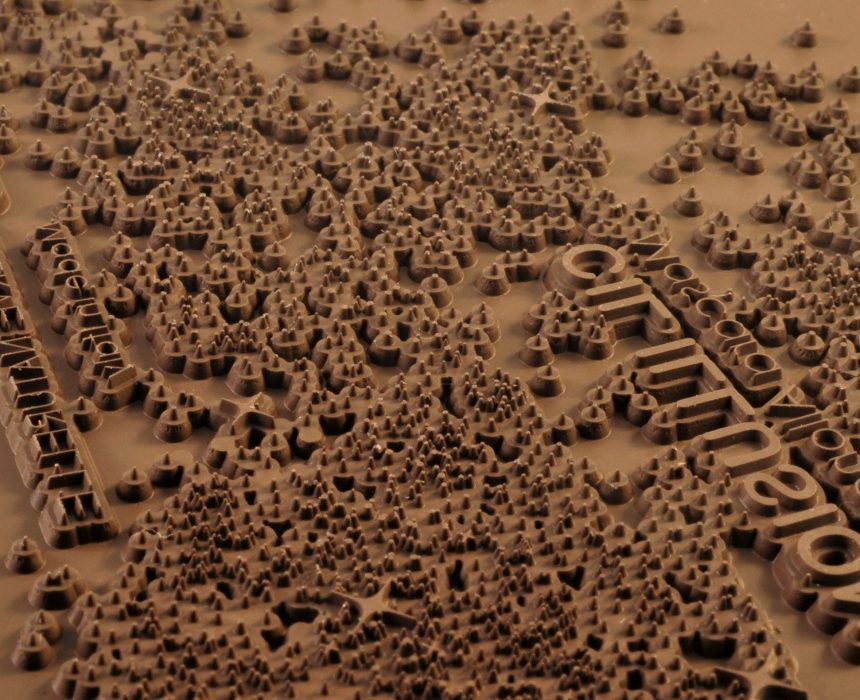

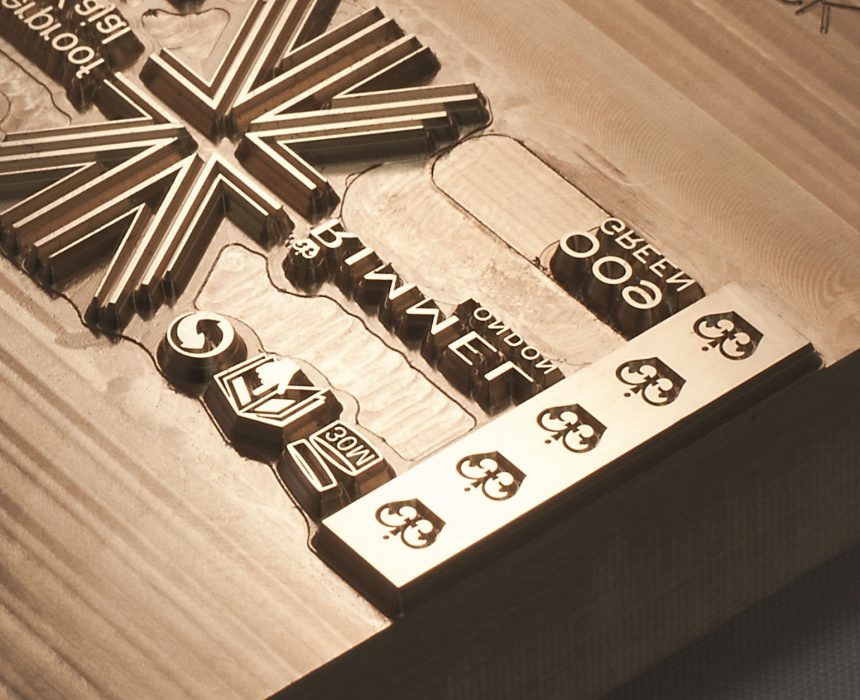

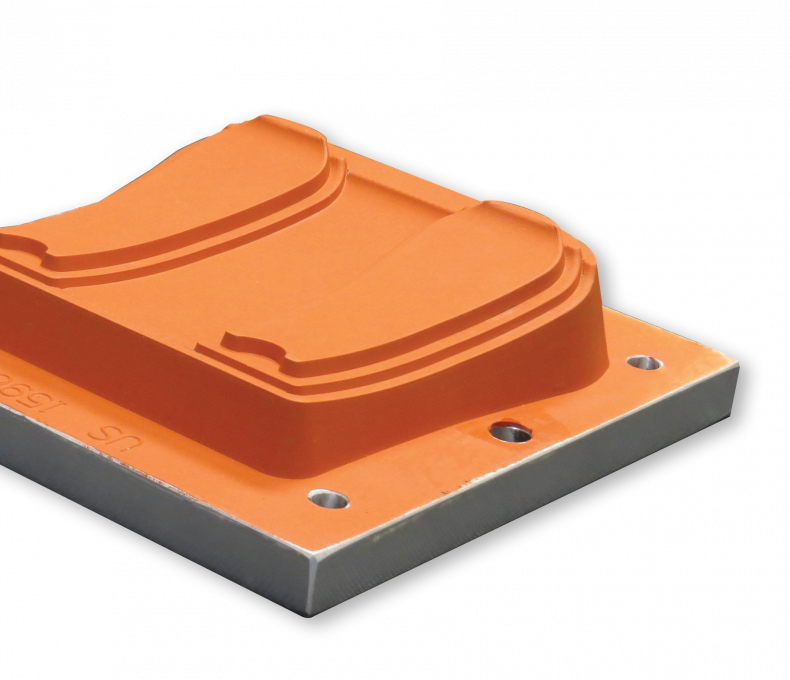

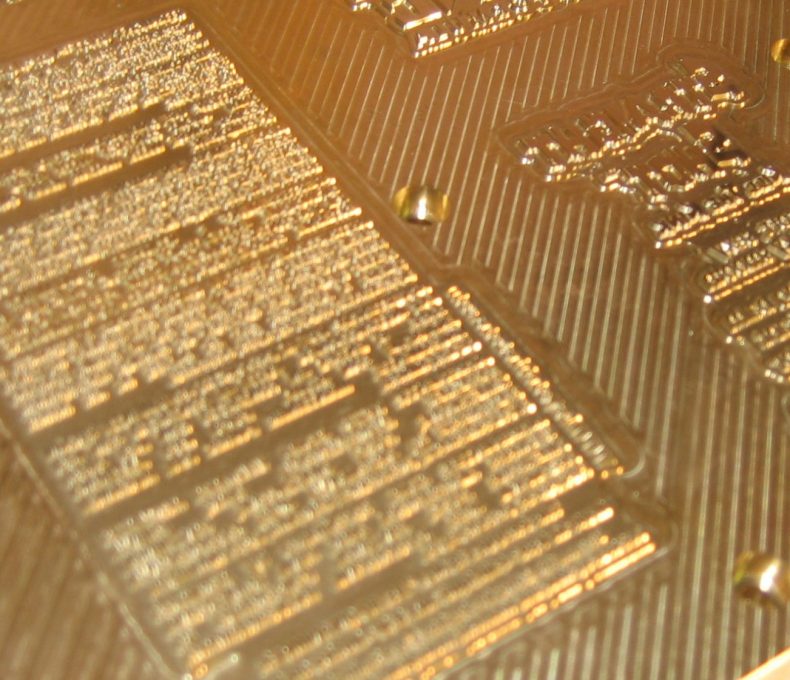

CER produces durable, high-precision silicone dies that deliver crisp, clean, impactful decoration to your part. Silicone rubber dies are used to hot stamp foil and heat transfers onto flat, contoured or cylindrical-shaped products.

Our dies provide excellent thermal conductivity, superior conformity to surface variations and high-impact visual performance with wide range of foils.