Custom Hot Stamp & Heat Transfer Equipment

Technology Designed for Your Requirements

In the world of product and component decoration, each project is significantly different from the ones that come before and after it.

Different part geometries and substrates are used. Required artwork comes in various levels of complexity. Different quality control and product handling requirements arise as well as different throughput speed requirements. There is also a significant level of difference in the expertise level of system users at different facilities.

All of these facts make custom hot stamp and custom heat transfer machines a very attractive solution.

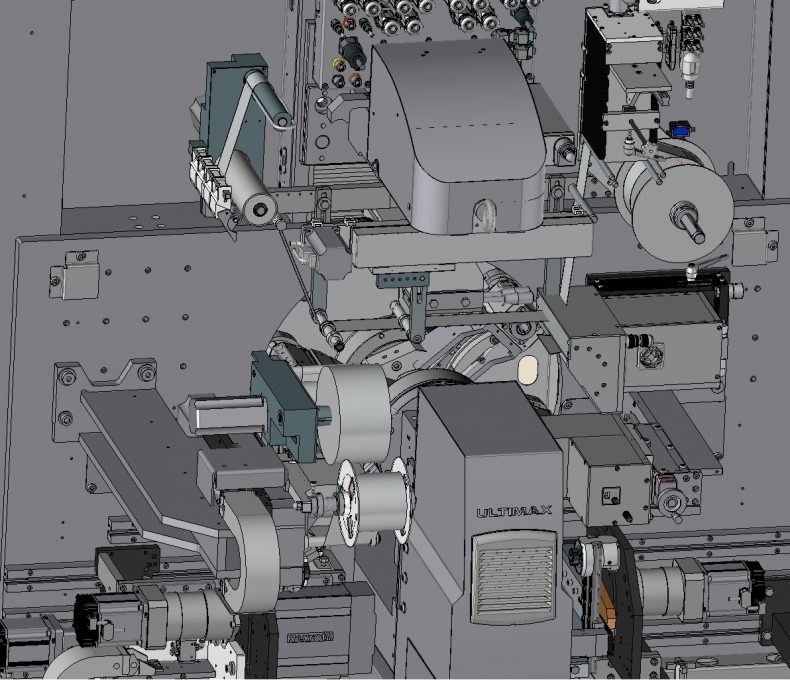

A majority of CER systems are custom-made. We carefully tailor each element to meet the specific requirements of your product (substrate, geometry, volume, artwork, etc.). We also work closely with partners to integrate material handling elements like loading and unloading systems in order to provide a total solution.

From start to finish- every aspect of your hot stamp or heat transfer solution can be custom tailored to your precise requirements. Items that can be customized include:

- Pre-treatments

- Feeding systems

- Throughput speeds

- Quality control vision systems

- Product handling

- Special ejection system – designed belts, countering systems

Our strategic process allows us to confidently identify the optimal solution for your product decoration challenge.

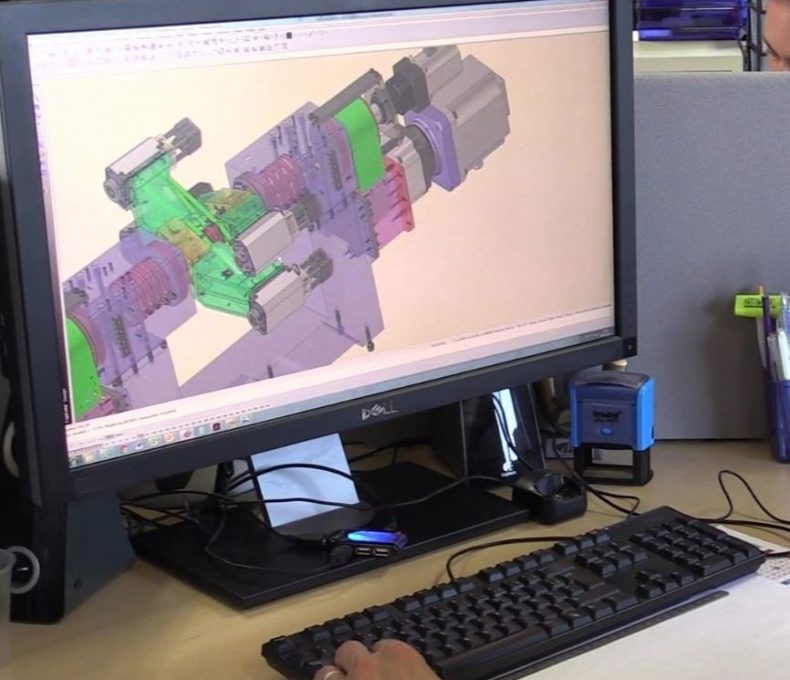

Our skilled engineers apply their decades of experience to anticipating performance needs (so you don´t have to) To best understand your precise requirements, we carefully explore a myriad of considerations including:

- Artwork complexity, size, location

- Production volumes required

- Substrate characteristics (dimensions, tolerances, surface features, etc.)

- Consumable quality requirements

(foil, heat transfer label, dies, etc) - Production Workflow (in-line and off-line elements)

- Customer engineering skill level

- Safety requirements

- Application or market-specific performance requirements

- Compliance/validation requirements (possible integrated vision system)

Once our engineering experts have a comprehensive understanding of your needs, they being the process of matching these needs to available technologies. The elements we consider include:

- Artwork generation or modification

- Required automation performance

- Stamping equipment format (vertical, peripheral, etc) and characteristics

- Die options – geometry & formulation adaptation

- Foil/film/transfer label requirements

- Fixture options

When our engineering experts have completed a comprehensive study of your needs and carefully mapped out technology alternatives, we can confidently present a hot stamp or heat transfer solution designed for absolute optimal performance for your unique application.