Silicone Stamping Dies: What Are They?

An Introduction

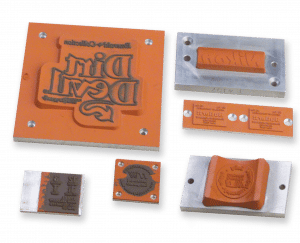

What ARE silicone stamping dies?

Hot stamp dies carry graphics that are transferred via pressure to the surface of a product or component. Silicone hot stamp dies are made of specially formulated silicone. This silicone is engineered to withstand the extreme pressure and high temperatures associated with hot stamp applications.

How are silicone dies used?

Silicone rubber dies are widely used for the application of hot stamp foil and heat transfer labels onto flat, contoured, or cylindrical-shaped products

Types of Silicone Dies

Silicone stamping dies can be made of a variety of silicone formulations. In addition to different silicone formulations – flat, contoured, crowned, and multi-level shapes are available. Silicone dies can be either photo-etched or machine engraved and can feature either single or dual durometers with a durometer range of 50 to 95 on the Shore A Scale.

An expert die manufacturer can help you select the optimal formulation for your unique performance requirements.

Silicone Die Benefits

Silicone stamping dies offer a wide range of performance benefits. These include:

1) A unique ability to conform to surface variations

2) Excellent thermal conductivity and heat conduction properties

3) Strong silicone-to-metal bond

4) Reduce stamping pressure (when compared to the use of metal dies)

and

5) High-impact visual performance with pigment, metallic, holographic or prismatic foils.

Benefits of Silicone Dies from CER

We combine market-leading die design expertise with cutting-edge art reproduction capabilities to ensure customers have the tools needed to achieve highly repeatable, superior decoration that will allow them to stand out in a crowded market.

- Up to 90x faster die changeover speeds (toolless Magnetic Quick-Change Die Mounting)

- Up to 50% improvement in mounting accuracy (Magnetic Quick-Change Die Mounting)

- Application of texture to the die surface to eliminate voids caused by air entrapment.

- CNC machine engraved molds for crowned, contoured and multi-level stamping

- Market-leading die capacity

Would you like additional information?

Please get in touch. We would love to hear from you.