Our Team

Our talented team is the foundation of our success at CER. Our deep expertise in both the equipment and consumable side of hot stamp and heat transfer processes combined with the proactive, innovative spirit of our talented team allow us to deliver superior product decorating solutions.

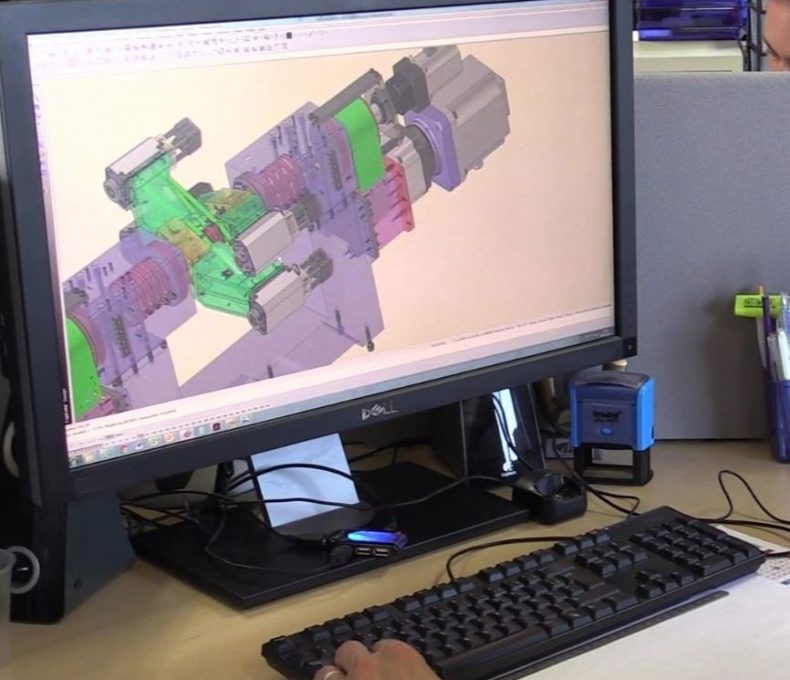

CER’s highly skilled engineering team has a combined total of over 100 years of hot stamp, heat transfer expertise. Over the past decade our engineering team has garnered impressive patents related to high speed movement of mechanically automated parts.

Our Optimal Solution Identification team has decades of experience testing and building hundreds of systems carefully tailored to precise environmental and application performance requirements. Our team will work closely with you to understand your unique application before recommending an optimal solution carefully matching your specific requirements.

Experts in our Graphics Department have an average of over 10 years experience transforming your artwork into highly repeatable decoration.

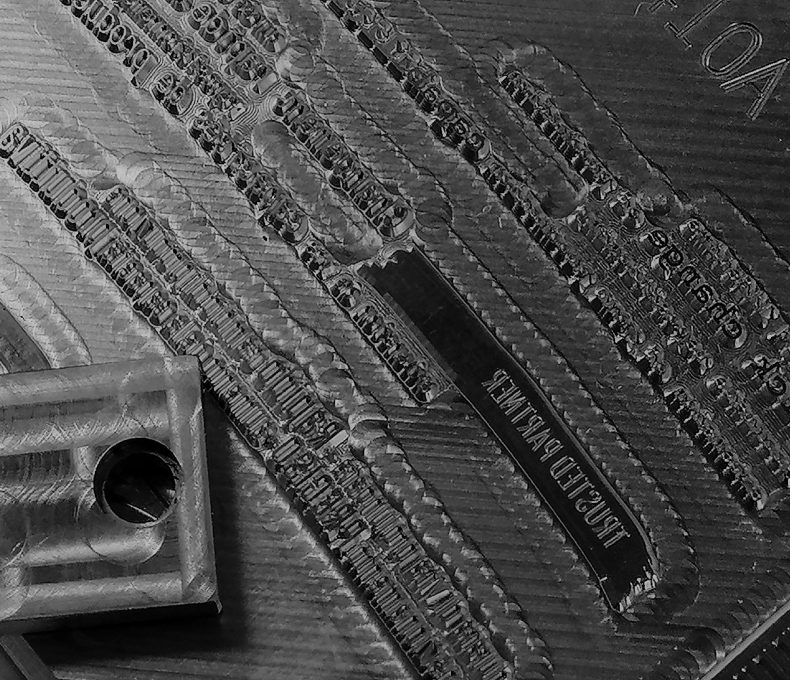

Armed with advanced design software and technology, we translate your artwork into precision silicone and metal hot stamping dies. Our art development services include art modifications, functional design, film development and full proofs.

Our expert Foil Color Match team uses a robust process to enable quick and accurate matches with the largest color and texture range in the market.

Our Die & Roller Department produces durable, high-precision silicone dies & rollers that deliver crisp, clean, impactful decoration to your part. Our Die & Roller Department stands out for ensuring highly repeatable, quality decoration.

CER designs each training in-house or on-site training session to meet specific customer needs. Topics frequently addressed include hot stamp & heat transfer theory, tooling selection/design, consumable selection/design, machine set up/maintenance, and troubleshooting. CER is also a fully certified DataDock training provider.

Members of our Technical Support team, have on average over 10 years of experience each in highly complex decorating systems. We provide support when and how it is needed. We are proud that out of all reported technical issues, less than 3% require service visits and 95% are resolved same day.

Our expert assembles, technicians and electricians build highly precise machines designed to deliver highly repeatable decoration in the most efficient, reliable and user-friendly way.

Our Accounting, Human Resources, Purchasing and Sales Teams lead the way on countless behind-the-scene tasks that make all of our other services possible. They are a key player in our ambition to be your Trusted Partner for product decoration.

David Mandon is the General Manager of ITW CER. He pulls from more than 25 years of manufacturing and leadership experience to ensure that CER lives up to its potential in serving as a Trusted Partner for product decoration.

Jennifer Perr is the General Manager of the ITW Industrial Decorating Solutions (IDS) Division.

She pulls from her more than 25 years of Senior-level leadership and from her diverse background in marketing, operations, innovation, sustainability, and sales management to help ensure that ITW CER and our sister companies – ITW UNITED SILICONE, ITW TRANSTECH and ITW MORLOCK are able to deliver on our pledge to be a Trusted Partner for Product Decoration.