Hot Stamp & Heat Transfer Equipment

Product Decoration Machines

CER provides a complete range of hot stamp and heat transfer equipment. Our systems come in both standard and custom formats and can be used as stand-alone units or as part of larger automated systems.

Our machines decorate on numerous substrates- most commonly plastic, aluminum or glass.

We decorate products in a number of shapes including – cylindrical, conical, flat, square, oval and more.

Our equipment is known for delivering highly repeatable precision decoration at very high speeds with superior efficiency and reliability. Many of our hot stamp and heat transfer machines are completely unique-in-the market.

ITW CER is widely regarded as an industry leader in high-speed rotary and linear automations for hot stamp and heat transfer decoration. We have over 80 years’ experience producing thousands of automated solutions.

Our equipment, robust project management and targeted market-specific expertise allow us to provide automations tailor-made for optimal performance on your unique application. We have especially deep expertise in the design of automated systems for cosmetic, fragrance, spirits, closures and automotive applications.

Elements frequently incorporated into automated systems include screen printing, loading feeders, feeding diverters, vision quality control and outbound conveyers.

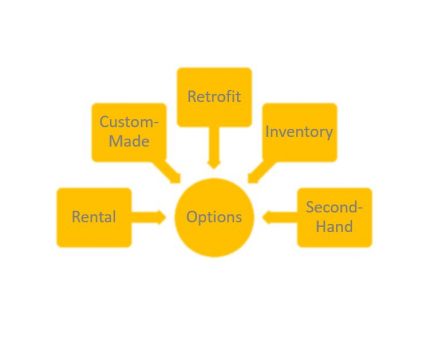

While a majority of our systems our custom-made, ITW CER does also provide select models from inventory for projects on a tight timeline. We can adjust these bases adding custom tooling, material handling, vision systems, foil advance and other elements. We also provide options for equipment rental as well as second hand machine purchases.