Hot Stamp for Fragrance and Glass Cosmetic Packaging

Market Leading Efficiency & Strong Visual Impact

How is hot stamp decoration used to decorate fragrance and other glass cosmetic packaging?

Hot Stamp equipment is often used to apply decoration, branding and general information such as ingredients or instruction -on perfume and cologne bottles as well as on glass cosmetic packaging. Visual impact plays a very large role in marketing these items.

What is unique or special about decorating on fragrance and glass cosmetic bottles and jars?

Like in most markets fragrance and cosmetic brands and their suppliers require repeatable, efficient, high quality decoration. Due to the competitive nature of the fragrance and cosmetic markets- high end visual impact is also essential. Quality decoration conveys a premium quality to packaging and allows brands to stand out from their competition.

In the past this process used to be quite costly! Glass manufacturers and glass contract decorators relied on highly expensive decorating process to apply real gold or platinum to their fragrance or cosmetic bottles to achieve “luxury” visual appeal.

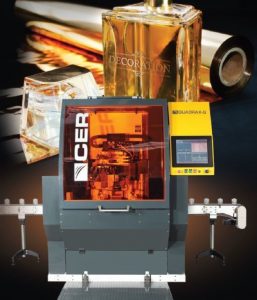

Today, CER has made it possible to achieve this same strong visual impact at a fraction of the cost. At the same time, options have grown. Today we can also provide a wide range of additional metalized colors to help brands differentiate themselves.

What kind of hot stamp decoration is possible on glass fragrance bottles and glass cosmetic bottles and jars?

Hot stamp decoration can provide fragrance and glass cosmetic bottles/jars with a premium look and strong visual impact. Up to 360 degree decoration can be applied to a wide range of bottle shapes including square, round and oval. A range of bottle sizes can also be decorated starting from min-travel bottles up to large glass bottles.

What products and services does CER offer for fragrance bottle and glass cosmetic bottle/jar decoration?

CER provides everything a fragrance or cosmetic brand could need for glass package decoration. Our services range from concept support through completed product handling. We have a wide range of systems, supplies and services uniquely tailored to supporting decoration of glass fragrance and cosmetic packaging.

What type of hot stamp equipment does CER provide for FULLY-automated glass bottle decoration?

Our QUADRAX machine is a flexible, versatile system for automated decoration of regular and irregular glass surfaces. The system´s flexibility also allows it to print small parts.

QUADRAX can decorate at speeds of up to 2,500 parts per hour- twice the printing speed of semi-automated systems. A special double silicone roller allows for printing in two areas or in two colors. This roller allows for compatibility with up to 30% more parts than with comparable systems for greater flexibility.

What type of hot stamp equipment does CER provide for SEMI-automated glass bottle decoration?

CER´s N240 Hot Stamp Equipment is tailored to provide single pass, large area decoration for semi-automated lines. The N240 is a versatile system compatible with a wide range of different container shapes and sizes.

What types of hot stamp supplies does CER offer?

CER produce supplies with market-leading precision ensuring you highly repeatable decoration print-after-print. Our dies, fixture/tooling sets, foils, rollers and sheets are widely considered best-in-class. We have also developed a specialty screen printing primer specifically for hot stamp decoration on glass.

CER produce supplies with market-leading precision ensuring you highly repeatable decoration print-after-print. Our dies, fixture/tooling sets, foils, rollers and sheets are widely considered best-in-class. We have also developed a specialty screen printing primer specifically for hot stamp decoration on glass.

Why is primer needed for hot stamping on glass?

Hot stamp decoration on glass containers requires the application of a screen print primer. This primer is what the hot stamp foil adheres to. Poor primer application or improper primer curing has a significant negative effect on visual impact. CER offers a specialized screen-print primer ink as well as advanced expertise to ensure this process is perfectly and seamlessly integrated into your line.

Hot stamp decoration on glass containers requires the application of a screen print primer. This primer is what the hot stamp foil adheres to. Poor primer application or improper primer curing has a significant negative effect on visual impact. CER offers a specialized screen-print primer ink as well as advanced expertise to ensure this process is perfectly and seamlessly integrated into your line.

What is unique about CER´s glass printing primer?

Our screen print primer has been specially formulated to optimize hot stamping performance on glass containers. Applied at high speeds, it ensures superior foil adhesion and quality visual impact. We offer both brown and grey colored primers for gold and silver foil respectively. CER also offers a range of additives to ensure performance is optimized for your unique application. We can match any color pantone or use our software to make your own color selection.

What kind of special screen print primer expertise and services does CER provide?

We go a step further than offering a specialized screen print primer.

Our deep familiarity with the entire decoration process allows us to provide expert insights into the types of additives (to harden, thicken or dilute) that will provide optimal performance on your application.

We also provide expert insights into identifying specific settings (like curing intensity and hot stamp printing temperature) that will ensure superior adhesion for your unique application.

In addition to providing a highly specialized primer and expert advice in how to best use in your application, we have very close relationships with leading screen print technology providers. We can work with them to seamlessly integrate the screen print process with your hot stamping process for a total decorating solution.

What types of fragrance and cosmetic brands does CER work with?

For over 50 years CER has partnered with many of the world’s leading fragrance and cosmetic brands as well as top industry suppliers.

Would you like to know more?

Please get in touch. We would love to hear from you.