Silicone Stamping Dies

Types, Uses and Benefits

What is a silicone stamping die?

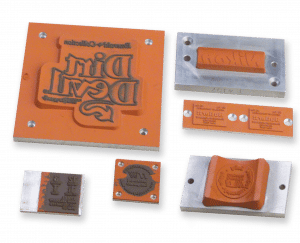

Hot stamp silicone stamping dies carry graphics which are transferred via pressure to the surface of a product or component. Silicone hot stamp dies are made out of specially formulated silicone rubber materials that are engineered to withstand the extreme pressure and high temperatures associated with the hot stamp decorating process.

How are silicone stamping dies used?

Silicone rubber dies are widely used for the application of hot stamp foil and heat transfer labels onto flat, contoured or cylindrical-shaped products.

What types of silicone hot stamp dies are there?

Silicone stamping dies can be made of a variety of silicone formulations. An expert die manufacturer can help you select the optimal formulation for your unique performance requirements.

Silicone Dies

- Flat, Contoured, Crowned, Multi-Level

- Single or Dual Durometer

- Photo-etched and Machine Engraved

- Die Finishing

- Traditional and Magnetic Mounting Formats

What are the general benefits of silicone dies?

Durable, high-precision silicone dies deliver crisp, clean, impactful decoration to your part. Our silicone dies provide superior conformity to surface variations, excellent thermal conductivity, high-impact visual performance with a wide range of foils.

What are the benefits of CER´s silicone dies?

| Benefits | Description |

| High Performance Formulations | Our Thermosil® formulation provides heat recovery to the die surface required for high-speed automated and long-dwell time applications. |

| Die Finishing | Our die finishing services include hole drilling, matching dovetail and special trims. We can save you time by providing a completely “ready-to-use” die. |

| Magnetic Die Mounting Systems | Provide for tool-less die changeovers in a matter of seconds while achieving up to 50% improvement in precision alignment performance. |

| Customer Service with Graphic Arts Expertise | Our Customer Service Reps are also graphic arts experts- eliminating “lost in translation” errors when it comes to manipulating and creating your artwork. |

| Superior Silicone-to-Metal Bond | Provides die longevity and repeatability from die-to-die for art location and overall thickness. |

What is the difference between hot stamp silicone dies and heat transfer silicone dies?

![]()

Though the hot stamp and heat transfer decoration processes are very similar, a difference can be seen in the dies used. The molds used for hot stamp dies carry the image to be used. They are more complex than the molds used for heat transfer decoration where no graphic image is carried on the die (the image comes from the heat transfer label itself).

What are key features to look for in a die manufacturer?

In addition to being able to provide you with expert advice on the type of silicone or metal die best suited to your unique application, a quality die supplier should provide:

Magnetic Quick-Change Dies

Time saving magnetic quick change dies can lead to up to 90x faster changeover speeds with up to 50% improvement in mounting accuracy

Precision Molds

Top die manufacturers should provide CNC machine engraved molds with crown or contoured surfaces to perfectly match part shapes/configurations.

Expert Tools – Eliminate Voids

Expertise on using texturing or screens and crowns to eliminate voids.

Large Capacity for Quick Die Turn Around

For example, CER´s large die capacity allows us to provide 1 to 3 day service on many die orders.

Would you like to know more?

Please get in touch. We would love to hear from you.