Types of Silicone Stamping Dies

What types of silicone stamping dies are available?

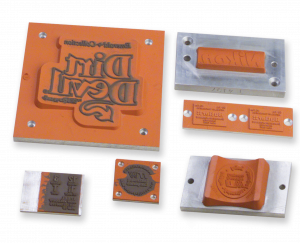

Hot stamp dies carry graphics that are transferred via pressure to the surface of a product or component.

A number of different types of silicone stamping dies are available. The shape, format, and construction of your silicone stamping die should be carefully selected to meet your unique performance needs.

Silicone Stamping Die Formats

For superior repeatability print-to-print and batch-to-batch, it is essential to select a die shape perfectly suited to your project. Both the geometry of the product or component to be decorated as well as the requirements of your specific artwork should be considered. If you have combination graphics, a dual durometer die could be helpful. Finally, it is helpful to consider whether you need die made from a photo-etched or machine-engraved mold.

CER offers the following types of silicone stamping dies:

| Shapes | |

| Type | Common Uses |

| Flat | Vertical stamping, peripheral and roll-on applications |

| Contoured | Decoration that precisely matches a contoured part |

| Crowned | Eliminate air entrapment or to allow for heat sinks in plastic parts |

| Multi-level | Accommodate small height differences in parts to be decorated |

| Durometers | |

| Type | Overview |

| Single Durometer | Dies ranging from 50 to 90 durometer to meet a wide variety of needs |

| Dual Durometer | Enhanced capability to stamp combination of fine and bold graphics or better conformity to part variation |

| Mold Styles | |

| Type | Benefits |

| Machine-Engraved |

|

How are silicone stamping dies made?

Silicone dies can be either photo-etched or machine engraved. CER specializes in machine engraved dies. There are several instances where machine engraved dies will provide superior results.

Case 1: Need for Multiple Reliefs

The first instance is when multiple reliefs are required for full part contact and/or support for character integrity. PhotoEtching produces a single relief. CNC engraving facilitates multiple reliefs and shapes such as crowns and full contours to match the shape of a part.

Case 2: Vertical Sidewalls

A second instance where Machine Engraved Molds may provide superior results is when vertical sidewalls are required for part clearance and/or precision foil transfer of lines or characters. CNC engraving (Machine Engraved Molds) provide this ‘control’ and repeatability from Die-to-Die.

Case 3: Extreme Precision Repeatability

Finally, Silicone Dies from Machine Engraved Molds are highly accurate and repeatable from Die-to-Die. For example – a Die used to stamp the lines of a ruler or another measuring device must create a finished part accurate to that scale of measurement. In other words, a hot stamped ruler must actually measure to 12 inches NOT 11 and 7/8!

What silicone formulations are used to make silicone stamping dies?

![]()

CER offers different silicone formulations each carefully engineered to meet specific performance requirements. Our Ultrasil Formulation is well-suited for demanding vertical and peripheral applications that require temperatures as high as 550 degrees Fahrenheit and/or high pressure. Typically Ultrasil is used in manually fed situations. Our second silicone formulation is called Thermosil. Like- Ultrasil, Thermosil offers exceptional heat resistance up to 550 degrees Fahrenheit. Thermosil also offers rapid heat recovery- making it well-suited to automated applications.

- Ultrasil – Often for manual applications

- Thermosil – Often for automated applications

What are magnetic dies?

Unique-in-the-industry, CER´s tool-less “Quick-Change” magnetic die mounting fixtures provide industry-leading changeover speeds and repeatability.

![]()

Simplified Changeovers

With Magnetic Die Mounting Fixtures, die changeover and set-up time is dramatically reduced. Magnetic die holding fixtures mount to your machine, allowing dies to be easily affixed eliminating the need for screws to secure the hot stamp die and providing

- Up to 90 x faster die changeover speeds

- Simplified, tool-less die changeovers

Improved Mounting Accuracy

Magnetic dies improve repeatability from die-to-die offering increased production and reduced downtime. The same pin and slot locations are used in both the die-holding fixture and the die to guarantee precision artwork alignment from die-to-die. In fact, Magnetic dies provide

- Up to 50% improvement in mounting accuracy in some instances

What are the differences between hot stamp and heat transfer dies?

Though the hot stamp and heat transfer decoration processes are very similar, a difference can be seen in the dies used. The molds used for hot stamp dies carry the image to be used. They are more complex than the molds used for heat transfer decoration where no graphic image is carried on the die (the image comes from heat transfer label itself).

Why should you look for a die supplier with deep expertise in artwork?

Ensuring high-quality hot stamp decoration depends upon having BOTH artwork carefully designed for the application as well as Dies manufactured utilizing specifications tailored to the graphic’s requirements! Click here to learn more about the role of graphic design and die manufacturing working together for superior decoration.

CER Silicone Dies

Unmatched Efficiency

CER dies provide market-leading efficiency. For example, our magnetic quick change dies allow for dramatically faster changeovers and improved mounting accuracy.

Unmatched Art Expertise

CER has cutting-edge art reproduction capabilities to ensure customers have the tools needed to achieve highly repeatable, superior decoration that will allow them to stand out in a crowded market.

CER Die-Related Services

In addition to being able to provide you with expert advice on the type of silicone die best-suited to your unique application, a quality die supplier should provide:

Precision Molds

Top die manufacturers should provide CNC machine engraved molds with crown or contoured surfaces to perfectly match part shapes/configurations.

Expert Tools- Eliminate Voids

Expertise in using texturing tools and raised dies to eliminate voids.

Die Finishing Services

These should include hole drilling, matching dovetail, and special trims. Quality manufacturers can save you time by providing a completely “ready-to-use” die.

Graphic Arts Expertise

Finding a die supplier with significant Graphic Arts Expertise eliminates “lost in translation” errors when it comes to manipulating and creating your artwork.

Would you like additional information?

Please get in touch. We would love to hear from you.