Silicone Rubber Rollers

Market-Leading Silicone-to-Metal Bond and Superior Thermal Conductivity

CER silicone rubber rollers provide superior thermal conductivity and silicone-to-metal bond. Our highly-engineered rollers, carefully designed for optimal performance in each application are available with fast turnaround.

CER provides complete rollers (core plus covering) for use in hot seal, hot stamp and heat transfer applications. Our universal rollers can be used on our systems as well as in competitor systems.

Double the life of your cap band roller!

Rollers used for applying band decoration on caps have typically featured a band in the middle of the roller. CER´s innovative new double-banded rollers effectively double the life expectancy of rollers used to apply cap band decoration. Our double-banded rollers feature bands on both of the outer sides of the roller. When the silicone on one side of the roller becomes worn down and requires replacement- the roller can simply be reinstalled on the other side- effectively doubling the roller´s productivity.

Not looking to apply band decoration on caps? CER also has an innovative roller solution for nearly any kind of roller application. We are proud to introduce re-coatable (re-useable) silicone rollers.

When a silicone roller becomes worn down, customers can simply ship these rollers to CER. We will use our proprietary silicone-to-metal bonding process to re-coat the machined metal core with fresh, new silicone. Customers only pay for the cost of shipping and the new silicone coating.

Being able to reuse the machined metal cores of rollers significantly reduces waste. Not only is their less landfill- but new energy is not needed to produce new machined metal cores.

Re-coatable silicone rollers generate significant cost savings as the machined metal core of the silicone rubber roller can be reused. The machined metal is the costliest part of a silicone roller. Being able to reuse the metal roller core generates cost savings.

For smaller rollers, cost savings may be close to 50%. For larger rollers, cost savings can be as high as 250%!

Re-coatable silicone rubber rollers reduce waste AND expense.

Market-Leading Efficiency

- Innovative rollers significantly enhance efficiency

- Double-Banded Rollers double life expectancy of rollers used for cap band decoration

- Re-Coatable/Reusable Rollers allow users to preserve and reuse machined metal roller core generating significant cost and waste savings..

Market-Leading Size Options

- Diameters up to 240 mm and face lengths up to 240mm

- Market´s largest range of roller sizes.

Market-Leading Adhesion

- Our sister company, United Silicone, developed a proprietary system for chemically bonding silicone to metal cores.

- The result is market-leading adhesion without the need for glue or other adhesives.

Seamless Finish

- We can eliminate the appearance of the ‘meeting point’ seen in alternative production processes resulting in blemish-free contact and heat transfer.

Fast turnaround

- Often in 7-10 days if not faster.

Superior Repeatability

We surface grind each roller to ensure

- Precise measurements (OD and TIR)

- Smooth surface finish.

Significant performance benefits make silicone rubber rollers an ideal tool for a wide variety of applications.

- Silicone can eliminate air entrapment issues thanks to its ability to conform readily to surface variations in molded parts, ensuring smooth application of stamping foils and heat transfer labels.

- Silicone rollers are well suited for “tipping” or decoration of raised artwork as well as application to flat, curved and contoured surfaces.

- Silicone rollers are ideal for non-decorating applications requiring a non-slip surface for feeding/pulling films through a variety of machine applications

Rollers for:

- Hot stamp

- Heat transfer

- Heat seal

On:

- Extruded products

- Cylindrical shapes

- Large, flat surfaces

- Curved surfaces

- Raised surfaces

To Provide:

- Banding

- Tipping

- Laminating

- Hot stamping

- Heat transfer

- Feed & guide rollers

- Liner-less labels

Our silicone rubber rollers are available in 60 & 70 durometer in standard formats and 40-90 durometer for some formulations (Shore A Scale).

| Ultrasil | Externally heated (under a Roller Shroud) applications requiring temperatures up to 260°C |

| Thermosil | Internally heated applications requiring thermal recovery from the center of the roller core to the outside surface of the silicone roller. Withstands temperatures up to 260°C |

| FDA-3A | FDA and 3A Sanitary – Class 1 Test Specifications |

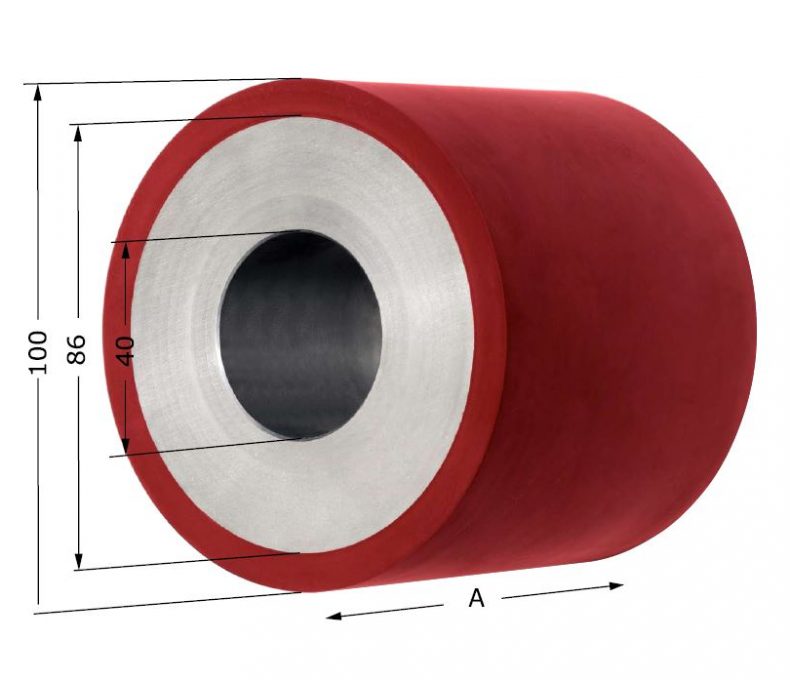

Our aluminum roller core are available in the following range of specifications

Outside Diameter

Standard diameters

– 100mm

– 115mm

– 130 mm

Face Length (A)

From 20 to 240 mm

Custom Core Design

To precisely match application requirements